Essential Mold Design Techniques for Efficient Manufacturing

- sean ED

- Dec 19, 2025

- 3 min read

Mold design is a critical aspect of manufacturing that can significantly influence production efficiency, product quality, and overall costs. In today's competitive landscape, understanding and implementing effective mold design techniques is essential for manufacturers aiming to optimize their processes and deliver high-quality products. This blog post will explore key mold design techniques that can enhance manufacturing efficiency, providing practical insights and examples to help you improve your operations.

Understanding Mold Design

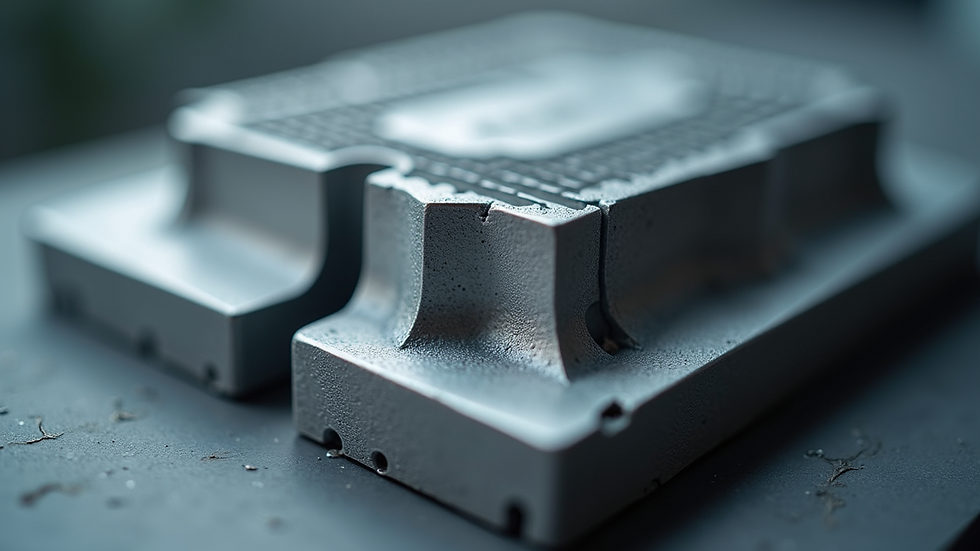

Mold design involves creating a mold that shapes materials into specific forms. This process is crucial in various manufacturing sectors, including plastics, metals, and ceramics. A well-designed mold can lead to reduced production times, lower costs, and improved product quality.

Key Components of Mold Design

Material Selection

Choosing the right material for the mold is fundamental. Common materials include steel, aluminum, and various alloys. Each material has its advantages and disadvantages, such as durability, cost, and thermal conductivity.

Mold Geometry

The shape and complexity of the mold directly impact the manufacturing process. Simple geometries are easier to produce and maintain, while complex shapes may require advanced techniques and technologies.

Cooling Systems

Effective cooling systems are vital for maintaining consistent temperatures during the molding process. Proper cooling can reduce cycle times and improve product quality by minimizing warping and defects.

Ejection Systems

Ejection systems are responsible for removing the finished product from the mold. A well-designed ejection system can minimize damage to the product and reduce cycle times.

Techniques for Efficient Mold Design

1. Design for Manufacturability (DFM)

Design for Manufacturability is a principle that emphasizes designing products in a way that simplifies the manufacturing process. By considering manufacturing constraints during the design phase, you can reduce production costs and time.

Example:

If a product requires complex features, consider whether these can be simplified or eliminated without compromising functionality. This approach can lead to a more efficient mold design and a smoother production process.

2. Modular Mold Design

Modular mold design involves creating molds with interchangeable components. This technique allows for greater flexibility and adaptability in production.

Benefits of Modular Mold Design:

Reduced Downtime: Quick changes can be made to accommodate different products without the need for a complete mold redesign.

Cost-Effective: Investing in modular components can save money in the long run by reducing the need for multiple molds.

3. Simulation and Analysis

Utilizing simulation software can significantly enhance the mold design process. These tools allow designers to visualize the molding process, identify potential issues, and optimize designs before physical production begins.

Key Advantages of Simulation:

Predictive Analysis: Anticipate how materials will behave during the molding process.

Cost Savings: Identify and resolve issues early, reducing the need for costly revisions later.

4. Incorporating Advanced Technologies

Integrating advanced technologies such as 3D printing and CNC machining into mold design can lead to more efficient manufacturing processes. These technologies allow for rapid prototyping and precise manufacturing, reducing lead times and improving accuracy.

Example:

Using 3D printing for creating mold prototypes enables designers to test and refine their designs quickly, leading to more effective final products.

5. Optimizing Cooling Channels

Efficient cooling is crucial for maintaining product quality and reducing cycle times. Optimizing the design of cooling channels within the mold can lead to significant improvements in production efficiency.

Tips for Optimizing Cooling Channels:

Placement: Position cooling channels as close to the mold surface as possible to enhance heat transfer.

Design: Use conformal cooling channels that follow the contours of the mold to ensure even cooling.

Best Practices for Mold Design

1. Collaborate with Cross-Functional Teams

Involving different departments such as engineering, production, and quality assurance in the mold design process can lead to better outcomes. Each team brings unique insights that can enhance the overall design.

2. Focus on Quality Control

Implementing quality control measures during the mold design process can prevent defects and ensure that the final product meets specifications. Regular inspections and testing can help identify issues early.

3. Continuous Improvement

Mold design is not a one-time task. Continuously seeking feedback and looking for ways to improve designs can lead to ongoing efficiency gains.

Example:

After each production run, gather data on mold performance and product quality to identify areas for improvement.

Conclusion

Effective mold design is essential for efficient manufacturing. By implementing techniques such as Design for Manufacturability, modular designs, simulation, and advanced technologies, manufacturers can significantly enhance their production processes. Remember to focus on collaboration, quality control, and continuous improvement to stay competitive in the ever-evolving manufacturing landscape.

By adopting these essential mold design techniques, you can improve your manufacturing efficiency, reduce costs, and deliver high-quality products that meet customer expectations. Start evaluating your current mold designs today and explore how these strategies can benefit your operations.

Comments