Choosing the Right Materials for Mold Manufacturing Success

- sean ED

- Dec 19, 2025

- 4 min read

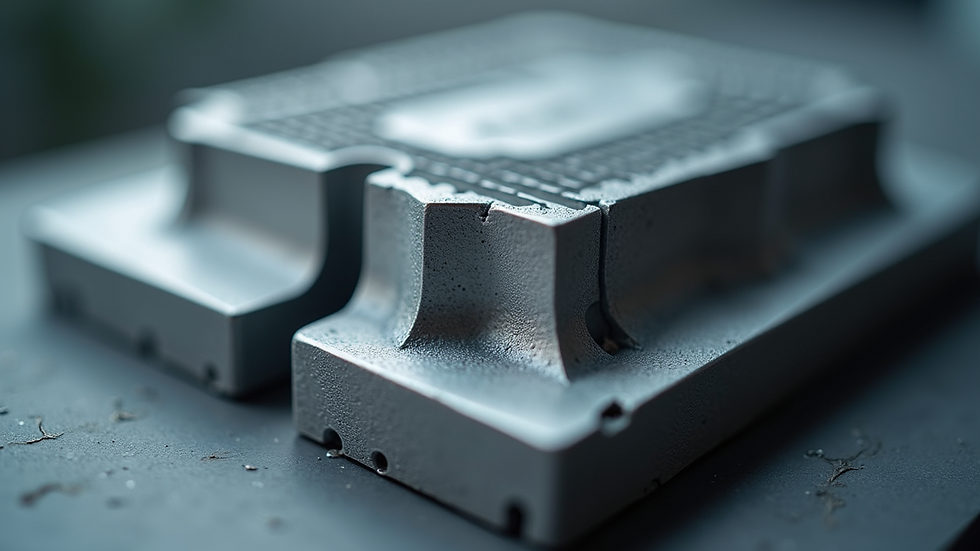

Mold manufacturing is a critical process in various industries, from automotive to consumer goods. The choice of materials used in mold making can significantly impact the quality, durability, and efficiency of the final product. Selecting the right materials is not just about cost; it involves understanding the specific requirements of the project, the properties of the materials, and how they interact with the manufacturing process. This guide will help you navigate the complexities of material selection for mold manufacturing, ensuring your success in this competitive field.

Understanding Mold Manufacturing

Before diving into material selection, it's essential to grasp the basics of mold manufacturing. Molds are used to shape materials into specific forms, and they can be made from various substances, including metals, plastics, and composites. The manufacturing process typically involves:

Designing the mold: This includes creating a 3D model that outlines the shape and features of the final product.

Material selection: Choosing the right materials based on the mold's intended use and production volume.

Fabrication: Using techniques like CNC machining, 3D printing, or injection molding to create the mold.

Testing and refinement: Ensuring the mold meets quality standards and performs as expected.

Key Factors in Material Selection

When selecting materials for mold manufacturing, consider the following factors:

1. Type of Mold

Different types of molds require different materials. For instance:

Injection molds: Typically made from steel or aluminum due to their strength and durability.

Blow molds: Often made from high-density polyethylene (HDPE) or polypropylene for flexibility and ease of use.

Compression molds: Commonly use silicone or rubber materials for their ability to withstand high temperatures.

2. Production Volume

The expected production volume plays a crucial role in material selection. For high-volume production, investing in durable materials like steel may be cost-effective in the long run. Conversely, for low-volume runs, aluminum or even 3D-printed molds might be more suitable due to lower initial costs.

3. Material Properties

Understanding the properties of different materials is vital. Key properties to consider include:

Thermal conductivity: Affects how quickly the mold can cool down after use.

Hardness: Determines the mold's resistance to wear and tear.

Corrosion resistance: Essential for molds exposed to harsh chemicals or environments.

4. Cost Considerations

While it might be tempting to choose the cheapest option, consider the total cost of ownership. This includes not only the initial purchase price but also maintenance, longevity, and the potential for defects in the final product.

5. Compatibility with the Process

Ensure that the selected material is compatible with the manufacturing process. For example, some materials may not withstand the high pressures of injection molding, leading to failures and increased costs.

Common Materials Used in Mold Manufacturing

Steel

Steel is one of the most commonly used materials for molds, particularly in injection molding. Its advantages include:

Durability: Steel molds can withstand high pressures and temperatures, making them ideal for high-volume production.

Precision: Steel can be machined to very tight tolerances, ensuring high-quality parts.

However, steel molds can be expensive and may require longer lead times for production.

Aluminum

Aluminum is a popular alternative to steel, especially for lower-volume production. Its benefits include:

Lightweight: Easier to handle and transport than steel molds.

Cost-effective: Generally less expensive than steel, making it a good choice for startups or small businesses.

Aluminum molds may not last as long as steel molds, but they can be a great option for prototyping or short runs.

Plastics

Certain plastics, such as polycarbonate and nylon, are also used in mold manufacturing. These materials are often chosen for:

Flexibility: They can be molded into complex shapes easily.

Chemical resistance: Ideal for molds that will be used with corrosive materials.

However, plastic molds may not be suitable for high-temperature applications.

Composites

Composite materials, such as fiberglass or carbon fiber, are becoming increasingly popular in mold manufacturing. Their advantages include:

Strength-to-weight ratio: Composites can be very strong while remaining lightweight.

Customization: They can be tailored to specific applications, offering unique properties.

Composites can be more expensive than traditional materials, but their performance in specialized applications can justify the cost.

Best Practices for Material Selection

1. Conduct Thorough Research

Before making a decision, research the properties and applications of various materials. Consult with suppliers and industry experts to gain insights into the best options for your specific needs.

2. Evaluate Long-Term Costs

Consider not just the initial cost of materials but also the long-term implications. A more expensive material might save money in the long run due to its durability and reduced maintenance needs.

3. Test and Validate

Whenever possible, conduct tests with sample molds to validate your material choices. This can help identify potential issues before full-scale production begins.

4. Stay Updated on Innovations

The field of mold manufacturing is constantly evolving. Stay informed about new materials and technologies that could enhance your production processes.

Conclusion

Choosing the right materials for mold manufacturing is a critical step that can determine the success of your projects. By understanding the various factors involved, including the type of mold, production volume, material properties, and cost considerations, you can make informed decisions that lead to high-quality products. Remember to conduct thorough research, evaluate long-term costs, and stay updated on industry innovations. With the right approach, you can ensure your mold manufacturing process is efficient, effective, and successful.

By focusing on these key areas, you can enhance your mold manufacturing capabilities and achieve better outcomes in your projects. Take the time to assess your needs and make choices that align with your goals, and you will be well on your way to success in the world of mold manufacturing.

Comments